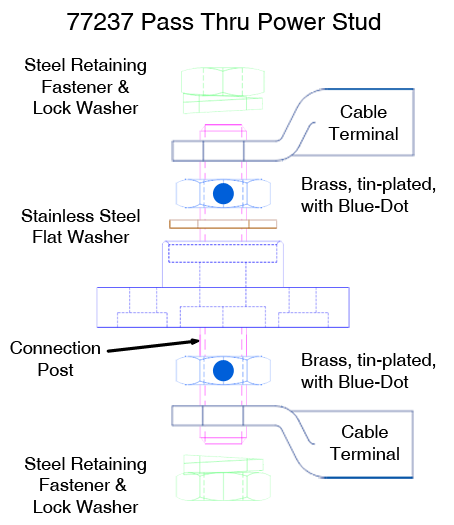

Blue Dot Technology

Conductive vs. Hi-Strength Retaining Nuts

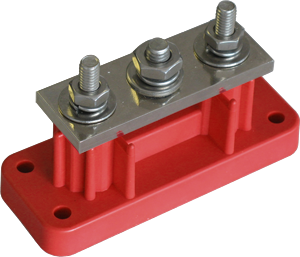

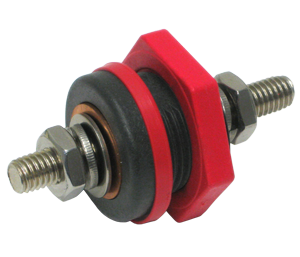

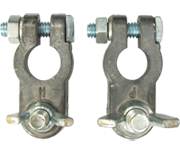

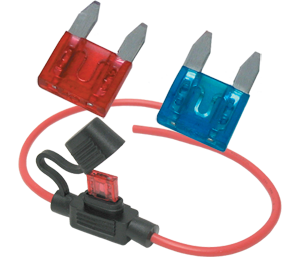

VTE Inc. uses two type of retaining fasteners:

- Conductive Fasteners

- Mechanical Fasteners

Conductive Fasteners

Our conductive fasteners are used where current will pass through the fastener. The electrical properties are such that conductivity is superior to mechanical fasteners.

- - Brass conductivity: 37%

- - Stainless steel conductivity: 2.4%

Mechanical Fasteners

Our retaining fasteners are used where current does not need to pass through the fastener. An example of this would be at the end of a connection post, to tighten an assembly.

Some key points:

- Conductive nuts include: brass, tin-plated brass. On some bus material: nickel-plated brass. Brass is used for its superior conductivity to stainless steel.

- Mechanical nuts: stainless steel, steel. Steel is used to tighten, or torque an assembly. Steel is much harder, and can handle higher torque before distortion.

- Brass and copper are more expensive than steel, and are only used where conductivity is required.

- Brass (or plated) nuts are marked by VTE with a Blue Mark. This is to notify the installer that the fastener is for conductivity positions only.

- Conductivity nuts are installed by the factory, and must be left in their original position.

- When installing multiple lug or ring terminals, washers are not recommended between terminals.

United States

United States